Scope of Services

We provide services of Thermal spray coating on machine parts or components.

It involves using a torch to heat material, in powder or wire form, to a molten or near-molten state. A gas propels this material to the target surface, creating a new layer. The coating can be a single element, alloy, or compound with unique properties that are often only possible through thermal spraying.

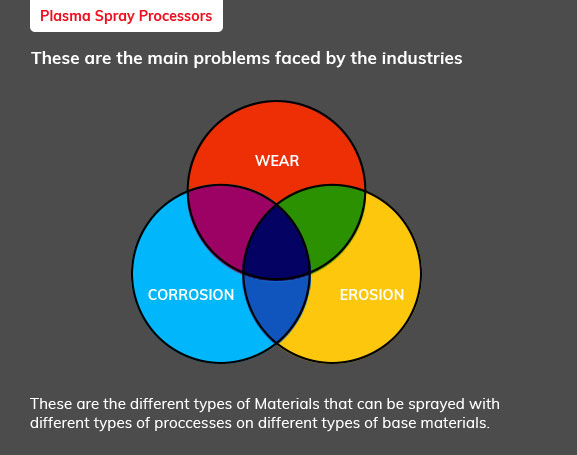

What are the typical problems and coating choices available to solve them?

Problems faced by Industry

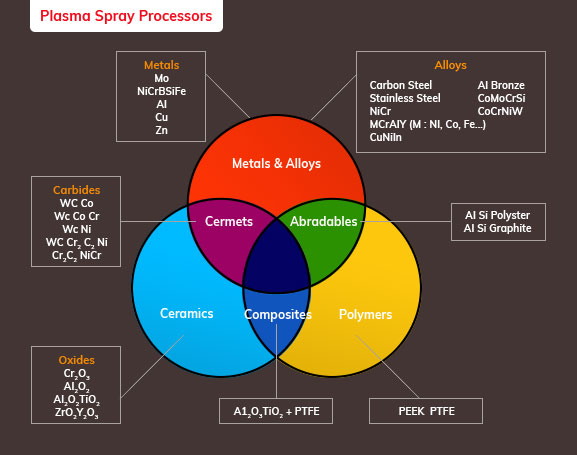

Types of Coatings

- How We Perform Thermal Spray Services on Your Components?

-

Customers send us their parts for coating and refurbishment. Our process includes thorough inspection, pre-grinding or machining, masking, blasting, coating application, and post-finishing. After these steps, we perform final inspections and send the parts upon customer approval.

- What is the price of thermal spray coatings?

-

The price of thermal spray coatings varies based on several factors

- Part drawing detailing geometry, dimensions, weight, base material, and coating area.

- Coating thickness, material, and surface finish.

- Material construction and its hardness.

- Part condition; additional machining or grinding for recoating if not new.

- Thermal spray parts typically cost 5 to 10 times more than hard-chrome plated parts but offer 2 to 5 times longer lifespan.

- What are the variables or customization available to our customers?

-

- Selection of coating composition, as indicated in the chart provided.

- Choice of coating thickness, ranging from 0.08 mm to 3 mm.

- Specification of desired surface finish for the coating, measured in Ra (roughness average), as outlined in the benefits section.

- What are things to take care before sending the job?

-

- Ensure the job is properly packed and rust-preventive measures are applied.

- Verify the job is free of pinholes, dents, and other surface defects.

- Perform pre-grinding operations and undercutting for the coating where necessary.

- Maintain 3-5 mm collars larger than the final finished size where possible.

- Remove sharp edges and debur the job before sending.

+91 9820718722

+91 9820718722