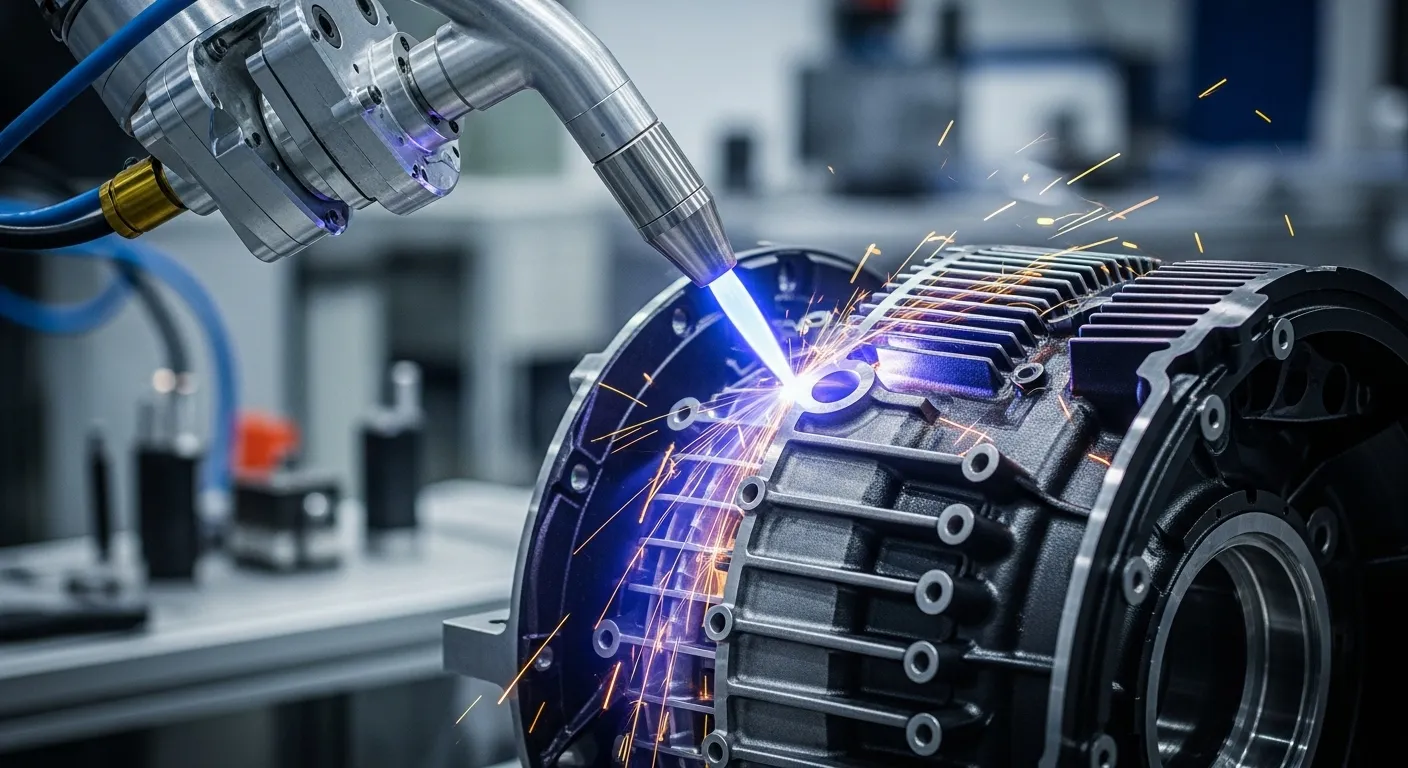

At Plasma Spray Processors, we deliver precision Twin Wire Arc Spraying solutions that extend the life of industrial components.

With over 40 years of experience, our coatings enhance performance and durability across steel, power generation, aerospace, and oil & gas industries.

Each project is tailored because no two components face the same wear, corrosion, or temperature conditions.

Request a CallbackTwin Wire Arc coatings form a dense, uniform layer that resists abrasion, erosion, and mechanical wear, keeping equipment operational longer.

The twin wire system produces a metallized coating that protects against rust, oxidation, and harsh environmental exposure.

Our coatings perform in extreme heat environments up to 1000°C, safeguarding parts in turbines, engines, and reactors.

With rapid coating buildup, the Twin Wire Arc process offers fast turnaround and reduced downtime for maintenance or refurbishment.

| Sr No. | Alloy/Material | Key Strength | Typical Applications |

|---|---|---|---|

| 1. | Zinc | Outstanding corrosion protection | Structural steel, bridges, pipelines |

| 2. | Aluminum | Lightweight corrosion resistance | Marine equipment, chemical tanks |

| 3. | Copper | High conductivity and adhesion | Electrical connectors and components |

| 4. | Stainless Steel | Chemical and heat resistance | Aerospace, reactors, and machinery |

| 5. | Nickel Alloys | Thermal and wear endurance | Turbine blades, pumps, valves |

Parts are cleaned, grit-blasted, and prepped to achieve strong mechanical bonding and adhesion.

Controlled coverage and coating thickness are maintained with precise masking and fixturing.

Twin wires melt by electric arc, spraying molten particles to form a dense, even protective layer.

Coated parts are polished, measured, and tested for hardness, adhesion, and ISO compliance.

Thousands of successful coatings across industrial sectors.

Consistent results through strict quality management and documentation.

Rapid service delivery, even for urgent rebuilds or maintenance.

We develop bespoke coating solutions for unique performance requirements.

Send your drawings or specifications to our team, and we’ll assess, recommend, and deliver the right Twin Wire Arc Spraying solution for your application.

Maharashtra | Gujarat | Tamil Nadu | Telangana | Andhra Pradesh | Karnataka

Mumbai | Navi Mumbai | Pune | Sangli | Rajkot | Baroda | Chennai | Coimbatore | Hyderabad | Bangalore