Thermal Barrier Coating -

Where Heat Stops and Reliability Begins

Efficient Insulation. Engineered Peace of Mind.

At Plasma Spray Processors, extremes are just another day at the office. Our thermal barrier coatings help your most valuable components shrug off high heat so they can get back to doing what they do best, without the meltdown, the downtime, or the drama.

Request a CallbackWhat is a Thermal Barrier Coating?

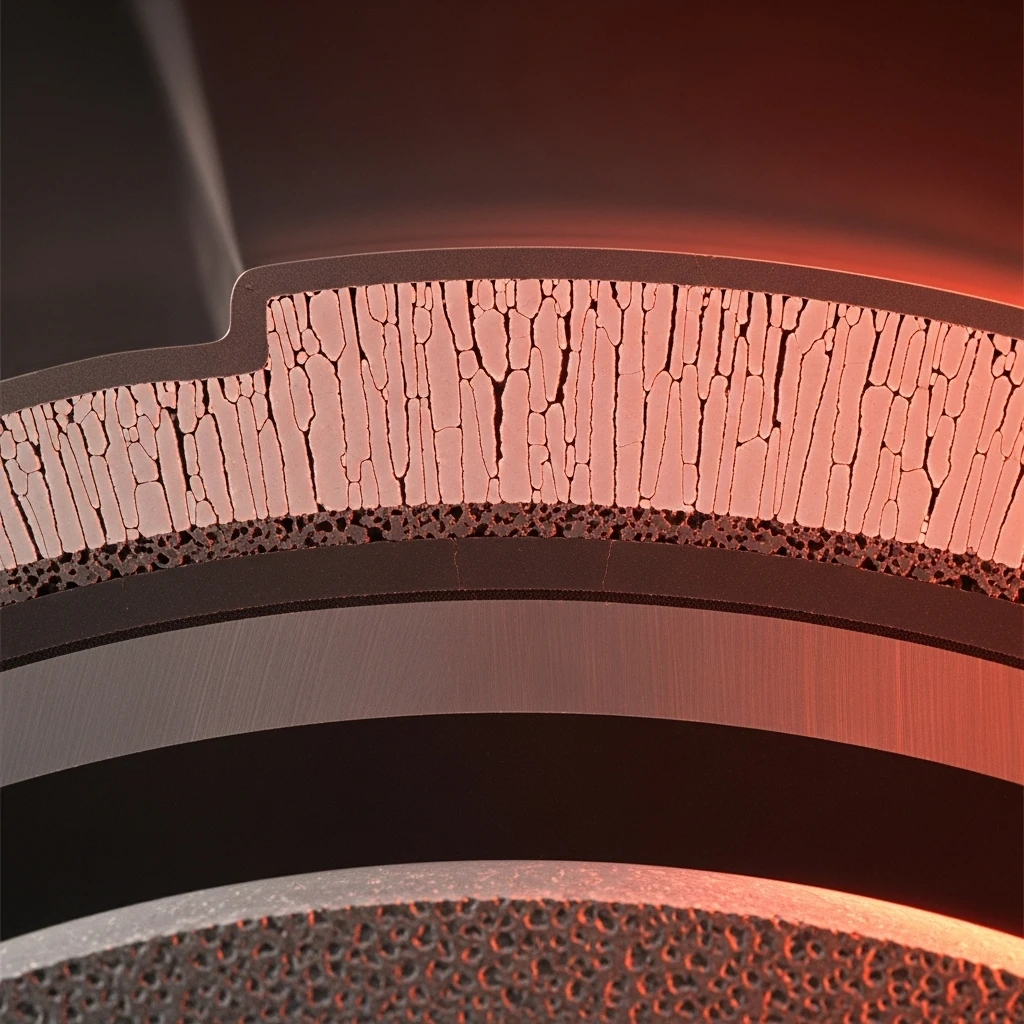

Think of TBC as your part’s very own “thermal armour” - a multilayered ceramic shield that keeps critical engine, turbine, or industrial surfaces running cool, even when things outside are seriously hot.

- Bond coat bonds it all together.

- Ceramic topcoat keeps the heat at bay, usually Yttria-stabilised Zirconia.

- Thermally grown oxide (TGO) layer for durability in harsh environments.

End result? Less heat where it does not belong, more life from every component.

Why Choose TBC from Plasma Spray Processors?

Up to 250°C lower metal temperatures, fewer surprises from sudden heat spikes.

Exceptional Thermal Insulation

Up to 250°C lower metal temperatures, fewer surprises from sudden heat spikes.

Handles the Heat

Ceramics tested for life at up to 1200°C, well above what most equipment ever sees.

Defends Against Oxidation & Corrosion

Specialized bond coats for long-term chemical and atmospheric resistance.

Lasts Longer (So You Can, Too)

Resists spalling, shock, and cycling, keeps your workflow uninterrupted.

Thermal Barrier Coating Materials:

| Sr No. | Material | What It Offers | Ideal Applications |

|---|---|---|---|

| 1 | Yttria-Stabilized Zirconia (YSZ) | Low thermal conductivity, high thermal shock resistance, stable up to ~1200°C | Gas turbines, diesel engines, aerospace components |

| 2 | Mullite | Low density, good mechanical strength, corrosion resistant, stable below 800°C | Diesel engines, lower temperature thermal barriers |

| 3 | Alumina (α-Al2O3) | High hardness, chemical inertness, high thermal conductivity | Added to YSZ coatings for improved oxidation resistance |

| 4 | Ceria (CeO2) + YSZ Blend | Improved thermal shock resistance and insulation | Enhanced YSZ coatings for thermal cycling |

Where Do TBCs Shine?

-

Turbine blades, vanes, combustors (Aerospace and Power)

-

Hot gas path and flame tubes

-

Exhausts, turbochargers (Automotive)

-

Reactors, high-enthalpy equipment (Process Industries)

If heat is the enemy, TBC is your easy win.

How It Works (No Surprises, Just Results)

Blast & Prep

Clean, grit-blasted surfaces for the best bond.

Bond Coat

NiCrAlY - classic, proven, and ready for duty.

Plasma Spray Ceramic Layer

YSZ topcoat, custom thickness, low porosity, applied with precision.

We Test. You Relax.

Every coating is measured, checked, and qualified to ISO/ASTM standards.

Technical Snapshot

-

Thickness: 100–300 µm (topcoat)

-

Hardness: 900–1200 HV0.3

-

Thermal Conductivity: ≤1.5 W/m·K

-

Operating Range: up to 1200°C

-

Bond Coat: NiCrAlY/MCrAlY, 75–150 µm

Why Work With Us?

Decades Doing This

40+ years of “seen it, solved it, coated it.”

ISO Process

Materials and controls that set the standard (and keep audits stress-free).

Proven Results

Reference case studies and technical data available for review.

It's Literally Custom

Every job is tuned for your environment and expected service life.

Frequently Asked Questions

Ready to Turn Down the Heat?

Let’s talk about a TBC solution that keeps your next project moving forward, with none of the guesswork.

Plasma Spray Processors - Thermal Barrier Coatings. More uptime, less worry.

Areas We Serve

Maharashtra | Gujarat | Tamil Nadu | Telangana | Andhra Pradesh | Karnataka

Mumbai | Navi Mumbai | Pune | Sangli | Rajkot | Baroda | Chennai | Coimbatore | Hyderabad | Bangalore

+91 9820718722

+91 9820718722