Tungsten Carbide Coating India

Engineered Protection, Every Time. No Jargon, Just Results That Matter.

At Plasma Spray Processors, our tungsten carbide coatings give your industrial components the edge, literally.

Designed for high stress, friction, and aggressive environments, these coatings are your safeguard against downtime and premature wear.

Request a CallbackWhy Tungsten Carbide Coating?

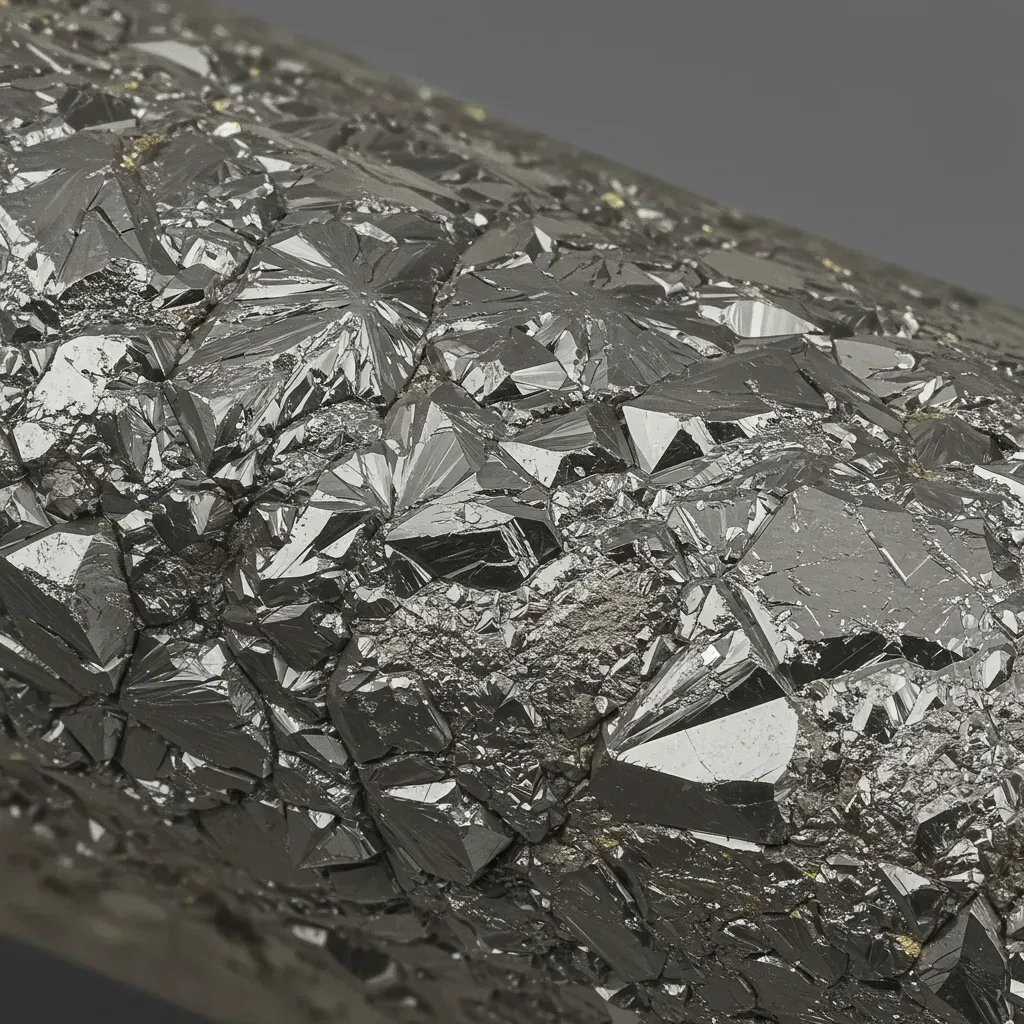

High Hardness (up to 72 HRC)

Tackle abrasive, sliding, and impact wear scenarios with a surface engineered for durability.

Superior Wear & Erosion Resistance

Proven performance for rotary shafts, rollers, pump sleeves, and plungers facing abrasive slurries or particles.

Corrosion Resistance

Maintains integrity under chemical, salt, and moisture attack.

Thermal Stability (up to 500°C for WC-CoCr grades)

Ideal for environments where productivity demands high-temperature operation.

Coating Materials We Use

We use premium-grade tungsten carbide and alloy-based materials to deliver exceptional hardness, wear resistance, and corrosion protection for industrial applications.

| Sr No. | Material | Property | Applications |

|---|---|---|---|

| 1 | Tungsten Carbide-Cobalt (WC-Co) | Outstanding wear and erosion resistance with high hardness | Pump sleeves, turbine shafts, mechanical seals |

| 2 | Tungsten Carbide-Cobalt-Chromium (WC-Co-Cr) | Excellent wear and corrosion resistance for severe operating environments | Hydraulic rods, valves, compressor rotors |

| 3 | Tungsten Carbide-Nickel (WC-Ni) | Improved corrosion protection with moderate wear resistance | Paper rolls, piston rods, and chemical equipment |

| 4 | Chromium Carbide-Nickel Chromium (Cr₃C₂-NiCr) | High-temperature oxidation and corrosion resistance | Boiler tubes, aerospace parts, and engine components |

| 5 | Nickel-Based Alloys (NiCr, Inconel) | Exceptional thermal stability and chemical resistance | Gas turbines, exhaust systems, and process valves |

| 6 | Cobalt-Based Alloys (Stellite Series) | Excellent galling, wear, and corrosion resistance | Cutting tools, bearing surfaces, and valve seats |

Technical Highlights

- 1. Typical Hardness: 62 - 72 HRC (Rockwell C)

- 2. Bond Strength: > 70 MPa

- 3. Coating Thickness: 50 to 400 microns

- 4. Porosity: < 1% typical

- 5. Surface Finish: Can be ground and lapped to a mirror finish

Industries We Serve

- Steel & Rolling Mills - Sink rolls, bridle rolls, run-out table rolls

- Textile - Guide, tension and calendar rollers

- Oil & Gas - Pump sleeves, valve stems, plungers

- Aerospace - Compressor blades, shafts, bearings

- Power Generation - Boiler tubes, shaft sleeves

- Automotive & Tooling - Dies, punches, forming tools

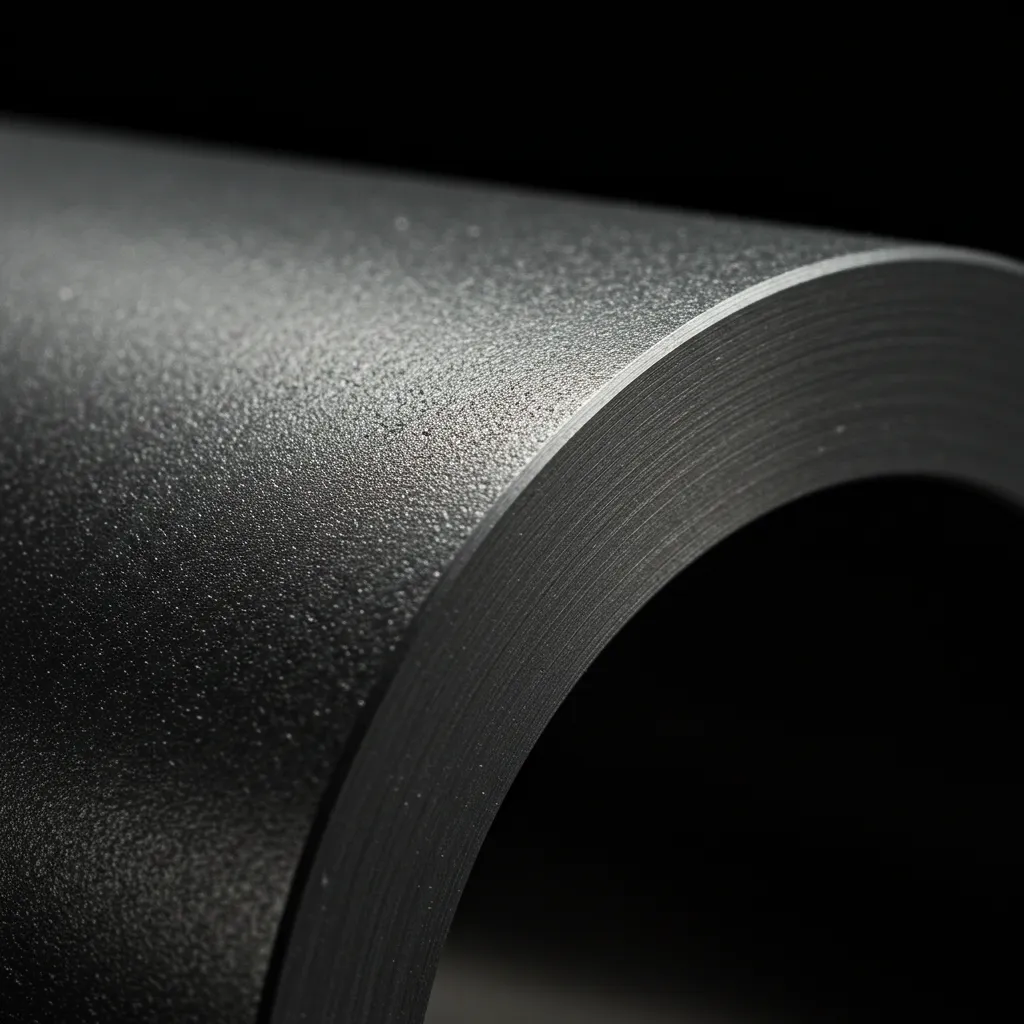

The Tungsten Carbide Coating Process

Surface Preparation

Grit-blasting to achieve proper surface roughness and maximize adhesion.

Material Selection

WC-Co, WC-CoCr, and WC-Ni grades, matched to your application’s mechanical and environmental demands.

Advanced Spraying (HVOF/Plasma Spray)

High velocity oxy-fuel or plasma arc systems deliver dense, strong, low-porosity coatings.

Quality Assurance

Coating is tested for hardness, thickness, adhesion (per ASTM C 633), and finish.

Why Work With Plasma Spray Processors?

4+ Decades Serving Indian Industry

Your local partner with global standards.

Certified Technicians & ISO Processes

Every part meets or exceeds client and ASTM/ISO benchmarks.

Pickup & Delivery Logistics

Fast turnaround, minimal disruption.

Proven Results

Reference case studies and technical data available for review.

Frequently Asked Questions

Do Not Let Wear Win.

Book tungsten carbide coating with Mumbai trusted name in surface engineering. Plasma Spray Processors: Raising the standard in wear, corrosion, and thermal barrier coatings for India’s industries.

Areas We Serve

Maharashtra | Gujarat | Tamil Nadu | Telangana | Andhra Pradesh | Karnataka

Mumbai | Navi Mumbai | Pune | Sangli | Rajkot | Baroda | Chennai | Coimbatore | Hyderabad | Bangalore

+91 9820718722

+91 9820718722